Materials

Home >> Materials

Expanded Polystyrene (EPS)

Expanded Polystyrene (EPS) is a non-toxic, lightweight plastic material, highly valued across various industries for its unique properties and sustainability. Its closed cellular structure allows for different densities, tailored to enhance performance and strength in diverse applications. It only contains 2% plastic, the remaining 98% is actually trapped air! The manufacture of EPS uses less than 0.1% of global crude oil as a feedstock however it can deliver up to 200 times its own resource in thermal energy savings. In the construction sector, EPS stands out for its durability, pest resistance, and use in insulated panels and civil engineering projects. Its non-toxic nature ensures safety in all applications.

In packaging, EPS’s shock-absorbing and thermal insulating qualities protect fragile items and perishables, aiding in safe transport and freshness extension. Additionally, EPS is utilized in lightweight applications like gliders, surfboards, and safety equipment such as children’s car seats and helmets, benefiting from its strength and shock-absorbency.

Crucially, EPS is 100% recyclable and can be repeatedly processed into new products, underscoring its role in sustainable practices. To understand more about this eco-friendly and innovative material, download our “How EPS is Made” PDF.

Expanded Polypropylene (EPP)

Expanded Polypropylene (EPP) is a a highly adaptable closed-cell bead foam, offers an extraordinary combination of features. It excels in energy absorption, multiple impact resistance, and thermal insulation. Additionally, it boasts buoyancy, resistance to water and chemicals, an exceptionally high strength-to-weight ratio, and is 100% recyclable.

EPP’s adaptability extends to various applications, thanks to its availability in different grades tailored to specific technical needs. High-density grades are crucial in areas where energy management is key, such as in automotive bumpers and interior passenger safety components. Meanwhile, low-density grades are perfect for packaging, and medium densities are widely used in furniture and other consumer products.

EPP is also food-safe, making it ideal for thermal-insulated food delivery containers, beverage coolers, and similar applications. Its resistance to microbial growth and compatibility with steam cleaning for sterilization further enhance its suitability for these uses. Explore the world of EPP and its myriad applications on our website.

Paper & Textile Accessories

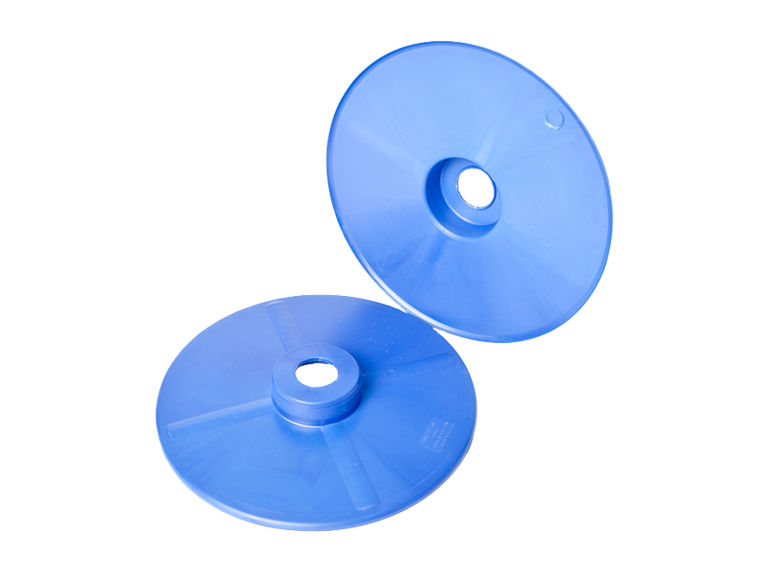

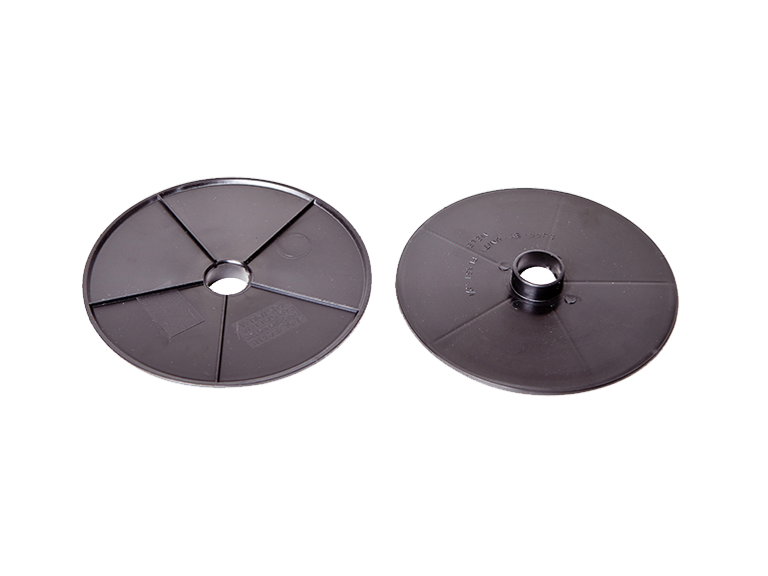

At Polyfoam, we take immense pride in manufacturing an extensive and diverse range of Spools and Reels, all proudly made in Australia. Our spools and reels are not just products; they are the embodiment of innovation, precision, and reliability, catering to a multitude of industries. They are essential in the organisation, storage, and transportation of various materials such as hoses, ropes, wires, cables, flexible extrusions, and chains.

Our spools and reels are designed with the utmost attention to detail, ensuring they meet the highest standards of quality and functionality. We understand that each industry has unique requirements, and that’s why our range is crafted to offer versatility and adaptability. Whether it’s for heavy-duty industrial use or for more delicate applications, our products are engineered to provide optimal performance.